From the beginning of recorded time people have milled grain as an important part of their diet. Along Bear Creek and the Yough several mills operated in the 1800’s, using water as the power source to turn the mill stones. As soon as the railroad reached town in 1889, local entrepreneur Leslie Friend built this building to specification to house an electric mill ‘package’ that arrived on one of the earliest trains to town.

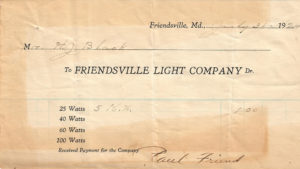

In anticipation of the millworks arrival, Leslie Friend developed a hydroelectric plant using water from an impoundment left idle by the old iron forge on the west side of the river across from the park. A water wheel powered generator sent electricity on wires to the mill, which distributed the power to street lights, businesses and private homes. At this time at the turn of the century, very few rural communities had power. The power to the town and the mill was shut off at 9 p.m. Homes had simple lighting with a single bulb hanging from the ceiling.

The first electric flour mill was built in 1887 in Laramie, Wyoming. Friendsville’s Unique Mill was possibly the first electric flour mill east of the Mississippi. It was a custom mill and area farmers could mill their various grains into several products such as buckwheat flour and cornmeal. Farmers would bring their various grains to the unloading dock (under the roof in the top picture) and pick up their finished product on the other side of the building where the train tracks were. Farmers paid for their milling by giving a share of their grain to the mill, which then shipped the products out by train.

Inside the building is a complex system of cup style conveyor belts that run inside an elevator leg (enclosed box) going from the ground floor to the very top of the building. The milled product was then diverted to other conveyor belts and sent to hoppers, bins or various sifters and other equipment for further processing or drying. The mill abruptly closed in the early 1960’s for reasons unknown and tools are still found there as if it was in operation

just yesterday.

Additional Video From Washington’s Mill